We occasionally get inquiries and manufacturing prints identifying a custom magnet shape using the abbreviation Neo. Because shorthand works – both internally and in discussions with our customers – we likewise sometimes refer to a Neodymium magnet as Neo or NdFeB. Of the rare earth element magnets, Neo magnets are the most commonly specified because they have the highest known energy product for their mass. One might possibly expect the Neo name to mean “new” – and that could be a reasonable assumption based on the fact that they were initially created relatively recently in 1984. The abbreviated name, however, actually comes from the element Neodymium – or Nd.

But there is a bit of a “new” twist to the naming story. In 1885, Carl Auer von Welsbach discovered that a substance known as (and previously misclassified as an element) ‘Didymium’ was actually a mixture of two entirely new elements. Welsbach successfully reacted Didymium to form nitrate salts, which he then fractionally crystallized from nitric acid to yield pink Neodymium and greenish-brown Praseodymium salts. Welsbach chose the name Praseodymium, which from Greek indicates ‘green twin.’ Compounds of praseodymium are green. Neodymium was named with ‘neos didymos’ – Greek for ‘new twin,’ reflecting Neodymium’s close association with praseodymium.

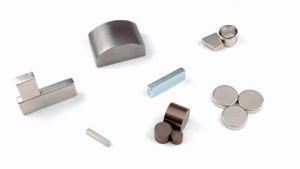

Neodymium magnets actually go by a few different abbreviations, but they all refer to the same magnet. This rare earth element magnet’s full name is Neodymium Iron Boron, so in addition to “Neo magnets” and “NdFeB magnets,” they are also sometimes referred to as “NIB magnets.” By the way, the full formula for the alloy NdFeB is Nd2Fe14B.

Neodymium magnets actually go by a few different abbreviations, but they all refer to the same magnet. This rare earth element magnet’s full name is Neodymium Iron Boron, so in addition to “Neo magnets” and “NdFeB magnets,” they are also sometimes referred to as “NIB magnets.” By the way, the full formula for the alloy NdFeB is Nd2Fe14B.

As previously stated, Neo magnets provide the greatest performance to volume ratio available, and work best up to 150º C. Samarium Cobalt (or SmCo5) magnets – another commonly specified rare earth magnet – are often better specified for industrial applications where temperatures will rise above 150º C.

It is important to note that Neo magnets typically require a protective coating, as they are prone to corrosion. One typical coating for NdFeB magnets is a triple layer plating of Nickel, Copper, and Nickel (Ni-Cu-Ni).

Whether you call them a Neo magnet, NIB, NdFeB, or Neodymium Iron Boron magnet, these are the same, high-quality industrial magnet. As is the case with all magnet materials, when selecting Neodymium for your application, it is important to use the correct Neodymium magnet grade, and to be aware of the magnet’s physical and environmental operating limitations.

For NdFeB magnet prices you can Request a Quote here.