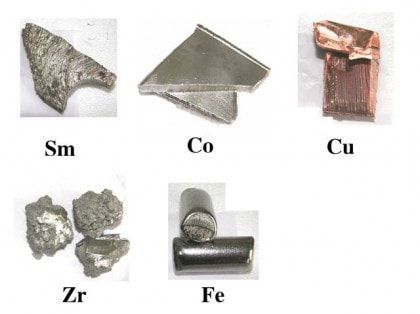

Fully dense Samarium Cobalt rare earth magnets are usually manufactured by a powdered metallurgical process. Micron size Samarium Cobalt powder is produced and then compacted in a rigid steel mold. The steel molds produce shapes similar to the final product, but the mechanical properties of the alloy usually inhibit complex features at this stage of the manufacturing process.

The Samarium Cobalt’s magnetic performance is optimized by applying a magnetic field during the pressing operation. This applied field imparts a preferred direction of magnetization, or orientation, to the Samarium Cobalt magnet alloy. The alignment of particles results in an anisotropic alloy and vastly improves the residual induction (Br) and other magnetic characteristics of the finished magnet.

After pressing, the Samarium Cobalt magnets are sintered and heat treated until they reach their fully dense condition. The rare earth magnet alloy is then machined to the final dimensional requirements and cleaned.

ITAR Registered & Compliant

We are registered and compliant with the International Traffic in Arms Regulations (ITAR). This qualifies us to work with items listed on the United States Munitions List (USML). We are also ITAR registered with the Directorate of Defense Trade Controls (DDTC).