In this second post of our blog series exploring magnetic couplers, we examine two different types of the commonly used “synchronous” style of magnetic torque coupler, which is a style of coupler in which the coupler’s output shaft speed equals the input shaft speed. The two primary versions of the synchronous style torque couplers that we will be discussing are the “Face-to-Face” type and the “Coaxial” type.

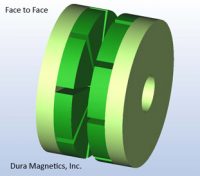

Face-to-Face

This style is comprised of disc-shaped assemblies. The discs have a single active magnet surface/side which must be “facing” in order to couple. The discs are usually comprised of several magnets affixed to a mild steel backing-plate, or housing. The severity of the operating environment will dictate the housing material for the magnet.

This style is comprised of disc-shaped assemblies. The discs have a single active magnet surface/side which must be “facing” in order to couple. The discs are usually comprised of several magnets affixed to a mild steel backing-plate, or housing. The severity of the operating environment will dictate the housing material for the magnet.

The Face-to-Face Coupler’s torque transfer capability increases as the Outside Diameter (OD) increases. This is because the effective magnet material acting to “couple” increases, as well as the resulting “lever-arm.” This can be a disadvantage, because the coupler may need to have a large OD to couple the target torque. A large OD may negatively impact the ability to integrate the coupler because of size. It also limits the rotational speed.

Face-to-Face Couplers are a good, low cost solution when the required torque, speed, and size restraints are moderate.

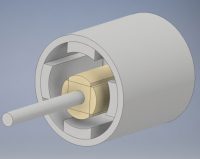

Coaxial

This style is comprised of an Inner Assembly (Half) and an Outer Assembly (Half). The active surfaces for this coupler type are on the Outside Diameter for the Inner Half and on the Inner Diameter for the Outer Half.

This style is comprised of an Inner Assembly (Half) and an Outer Assembly (Half). The active surfaces for this coupler type are on the Outside Diameter for the Inner Half and on the Inner Diameter for the Outer Half.

Unlike the Face-to-Face Coupler, the Coaxial Coupler’s torque transfer ability will increase as the axial length is increased, as well as when the diameter of the halves is increased. Increasing the axial length is the most common method of gaining torque transfer ability with a Coaxial Coupler. Increasing the axial length is also the most cost effective method when compared to increasing the Outside Diameter.

Unlike the Face-to-Face Coupler, the Coaxial Coupler’s torque transfer ability will increase as the axial length is increased, as well as when the diameter of the halves is increased. Increasing the axial length is the most common method of gaining torque transfer ability with a Coaxial Coupler. Increasing the axial length is also the most cost effective method when compared to increasing the Outside Diameter.

Coaxial Couplers are usually of higher cost than Face-to-Face Couplers, but they usually offer a space savings.

Contact Dura Magnetics for assistance in selecting the most optimal style of Torque Coupler for your application.