This Tech Talk article is the first in what will become a five-part series focusing on Magnetic Torque and Magnetic Linear Couplers. Magnetic Torque and Linear Couplers are used for applications where non-mechanical contact is desired. They are employed in high-vibration applications or where two operating environments need to be separated.

How Magnetic Torque & Linear Couplers Work

The magnetic field produced by permanent or electromagnets creates a condition by which a force can be exerted over a distance. This is fairly obvious to anyone who has handled a magnet and observed that a magnet need not touch an object in order to exert a force on it.

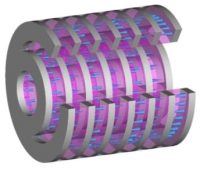

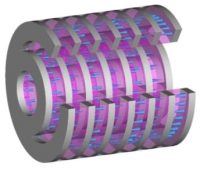

The ability to exert a force through a “gap” will also facilitate propagation of the object. This is most notable in a Torque Coupler, where two magnetic assemblies operate through a gap, and torque can be transferred from one assembly to the other without direct mechanical contact. A linear version of this “coupling” effect is also fairly common. Instead of a rotational force, a linear “coupling” force is transferred between the two magnet assemblies.

Types of Magnetic Couplers

To transfer torque, a rotational Torque Coupler can be employed. An example of this type of coupler is an impeller inside a pressure vessel driven by an external motor. The external motor is attached to one side of the Torque Coupler and the impeller, inside the pressure vessel, is attached to the second coupler half. The impeller is successfully “driven” by the motor, even though there is no mechanical contact, as the chamber wall separates the two coupler halves and operational environments.

To transfer torque, a rotational Torque Coupler can be employed. An example of this type of coupler is an impeller inside a pressure vessel driven by an external motor. The external motor is attached to one side of the Torque Coupler and the impeller, inside the pressure vessel, is attached to the second coupler half. The impeller is successfully “driven” by the motor, even though there is no mechanical contact, as the chamber wall separates the two coupler halves and operational environments.

Linear Magnetic Couplers transfer force in non-rotational applications. An example of this type of coupler is a rodless piston in a cylinder that is driven by pressurized air. A Linear Couple affixed to a piston located inside of the tube will transfer a linear force to an outside carriage affixed to the external coupler assembly. The outer carriage will follow the internal piston movement. Not only can the outer carriage act as a simple position locator, a large amount of force can be transferred between the two coupler halves.

Application Notes

Typically, the cost of a Torque or Linear Coupler exceeds the cost of common mechanical solutions, but couplers are employed when mechanical linkages are not feasible. One of the largest expenses of a coupler is the magnet component. For custom coupling devices, the magnet alloy must be minimized to yield a viable commercial design. The operating environment also adds cost and complexity. One half of the coupler is usually operating in an aggressive environment that may include:

Typically, the cost of a Torque or Linear Coupler exceeds the cost of common mechanical solutions, but couplers are employed when mechanical linkages are not feasible. One of the largest expenses of a coupler is the magnet component. For custom coupling devices, the magnet alloy must be minimized to yield a viable commercial design. The operating environment also adds cost and complexity. One half of the coupler is usually operating in an aggressive environment that may include:

- High pressure

- Temperature extremes

- Caustic liquids or gasses

- High degree of particulates or fouling agents

Please contact a Dura Applications Team member to assist with selecting the ideal coupler style and to discuss design considerations.