Dura utilizes 2D and 3D magnetic simulation packages to design engineered-to-order magnetic assemblies and magnet solutions for a wide range of industries, including:

Commitment to Technology and Design for Manufacturability

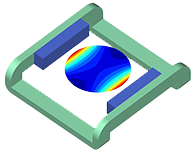

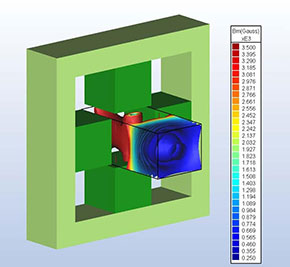

The professionals at Dura understand that our customers are not always certain about the existence or feasibility of a magnetic solution. To that end, Dura leverages its technical assets, including computer simulations with 2D and 3D FEA and Boundary analysis software to validate design concepts, thereby reducing product development time and expense, and ensuring manufacturability of the finished product.

By utilizing simulation software, a tentative solution can be generated, forwarded, and discussed with your design team. After preliminary models are reviewed, an informed decision can then be made on how or whether to proceed.

Reverse Engineering

Dura’s industry expertise and in-house capabilities allows us to reverse engineer an existing magnet or magnetic assembly to improve performance, enhance service life, quantify and qualify older designs, and reduce costs.

These capabilities include:

- 60+ years of knowledge in magnetics and magnetic design

- Hysteresisgraph used to quantify the magnetic characteristics of the magnet

- 2D/3D FEA Modeling

- Performance benchmarking of the application

Design Considerations

During the design phase of your project, it is important to consider the complexities associated with designing with magnetic materials. Not only is the magnetic performance of the magnet important, but also how the magnet will be integrated into the final solution.

The operational performance of a magnet material can be very challenging to predict. The magnet material used for your custom application may experience one or more of the following challenges:

- Environmentally unstable (Highly reactive and prone to oxidation)

- Gain or lose magnetic field relative to the operational temperature fluctuations

- Can experience irreparable harm at extreme temperature exposures

- Challenging to fabricate because conventional machine tools and machining methods are not feasible

- Challenging to design because the magnetic field density and force are not linear relative to distance

- Magnetic fields can create hazards for personnel and some electronic equipment

- Magnet alloy is difficult to machine, so common methods of retainment such as tapped holes, shoulders, through holes, and tapers are expensive to employ

If your potential vendor is not alerting you to these common manufacturing challenges during the quotation phase, you may be entering into a partnership with an order taker rather than finding a vendor capable of serving as your advocate, protecting your project from the common pitfalls experienced with magnetics manufacture. Dura Magnetics will provide a quote as per your drawing, observing the indicated details and specifications, and/or open a dialog, questioning the potential issues.

Commonly requested specifications attributed to conventional materials, such as aluminum, steel alloys, plastic, etc., are usually challenging to implement with magnets and magnetic materials. These specifications, usually indicated on a drawing by default, may add cost and complexity when manufacturing a magnet or magnetic assembly. It is important to review the relevance of these industry standard features and specifications when designing and specifying a magnet or magnetic assembly. Click to view a list of common, mistakenly applied, drawing attributes.

Optimization for Performance, Cost, and Price Volatility

Oftentimes the magnet alloy is the most costly part of an assembly and optimizing the magnet volume used yields financial savings. By optimizing a magnet design for an application using simulation software, Dura Magnetics can offer significant cost reductions. Relative to common commercial materials such as steel, aluminum, and plastic resins, the volume of Magnet Alloy manufactured in the world is quite low. Because of the low magnetic alloy production levels and small number of mines, refinery operations, and mills, price volatility is quite common. Using an engineering oriented approach to design, Dura Magnetics can optimize the magnet for your application specific product, reducing your exposure to price volatility.

Special Requirements

- DFAR (Specialty Metals Clause 252.225.7009)

- Export Controlled Items

- Conflict Minerals – Section 1502 Dodd-Frank

- REACH – RoHS – RoHS 2

Reverse Engineering

- AS9100D Certified

- Mil-Spec 45208A

- Coordinate Measurement Machines and Video Inspection System

- Magnetic testing equipment for measurements of Field Density and Field Strength

- Hysteresisgraph for magnetic characteristic measurement

Magnet and Magnetic Assembly Engineering and Product Development Specialists

Unlike some magnet design manufacturers that limit access to design and engineering staff, Dura understands that communicating with our engineering staff is the key to your project’s success. Making our engineering staff an outsourced extension of your company’s development team is mission critical. Our design and engineering team members remain engaged throughout the life of your project so as to ensure that a knowledgeable professional is always available to you to discuss your project.

If you are frustrated because potential vendors are not effectively communicating to you the nuances of a design or fabrication process, or if you have grown weary of hearing your application is too simple, too technically complex, then perhaps it is time to consider Dura. We are an engineering-oriented company that has the willingness and ability to understand industry, segment, language, and unique specifications.

Whether your project’s scope ranges from prototype development to production quantity runs, we welcome your magnet or magnetic assembly challenges and opportunity to provide you with best-in-industry solutions. At your convenience, explore a list of industry-specific application narratives requiring magnetic solutions and send us a note or drawing of your project. You can contact Dura by e-mail or call us at 1-800-492-7939. We look forward to becoming your magnet solutions partner.

DFARS & ITAR Compliance

Limited availability of Defense Federal Acquisition Regulation Supplement (DFARS) compliant material can make small magnet production runs costly. However, we stock various grades at our U.S. facility, enabling us to provide cost-effective, DFARS-compliant magnets for all customers if needed, regardless of project size or requirements.

We are also registered and compliant with the International Traffic in Arms Regulations (ITAR). This qualifies us to work with items listed on the United States Munitions List (USML). We are also ITAR registered with the Directorate of Defense Trade Controls (DDTC).