Most useful commercial magnets are anisotropic, which means that they are “Oriented” and have an “Easy” or preferred direction of magnetization. The orientation is developed in Cast and Sintered Alnico magnets during a “Heat-treatment” stage executed after producing the shape. This heat-treating step is where the magnet is heated to a target temperature and then cooled in the presence of an Alignment or Orienting field.

It is essentially impossible to magnetize the resulting anisotropic magnet alloy other than in the Direction of Orientation; however, various pole configurations can be achieved without conflicting with the magnet material’s orientation.

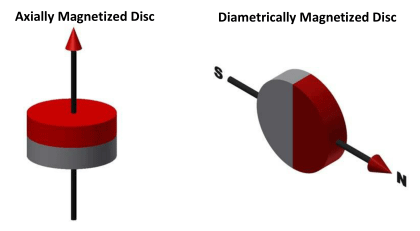

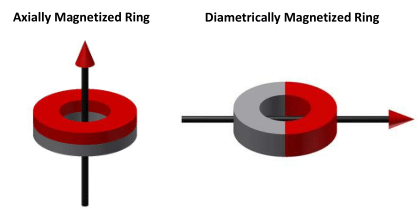

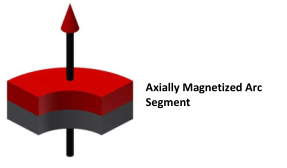

Below are conventional and standard industry options for the magnetization directions of Alnico Magnets.

Disc Geometry

Polarity Nomenclature: Typically the arrowhead indicates the North pole of the magnet. For symmetric geometries indicating the location of a particular pole is unnecessary, but for non-symmetric geometries identifying a particular pole location is very important.

Example: An axially Magnetized disc magnet does not require communication as to the NORTH pole’s position, but a radial arc does. One must indicate if the NORTH pole is to reside on the Inner Radius or Outer Radius.

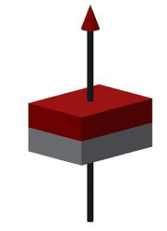

Block Magnet

The block magnet can be polarized in any direction.

Ring Geometry

Arc Segment Geometry

Circumferential:

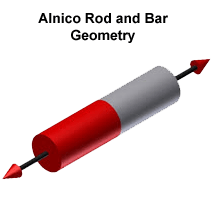

Rod and Bar Geometry

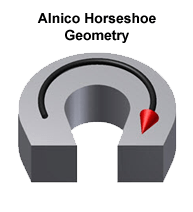

Horseshoe Geometry

ITAR Registered & Compliant

We are registered and compliant with the International Traffic in Arms Regulations (ITAR). This qualifies us to work with items listed on the United States Munitions List (USML). We are also ITAR registered with the Directorate of Defense Trade Controls (DDTC).